Wastewater treatment process modelling at its finest

WEST software is a sophisticated simulation tool used by operators and engineers to optimise plant design, operations and automation by targeting effluent quality, energy and cost.

Why WEST?

To compare and verify design alternatives for new treatment plants

See how WEST compares MLE, Bardenpho and UCT process configurations for a municipal WWTP

Watch WEST transform an existing facility’s phosphorus removal process

To optimise and upgrade existing treatment plants

To develop custom process models and new processes blocks

Track the effect of toxic chemical in a biological treatment system

To implement advanced control strategies of unlimited complexity

Evaluate various operational strategies with flexible control models, prior to their implementation. Automatically convert Matlab fuzzy logic controllers. Build fully customisable control systems using multiple control blocks. Easily navigate the model library and customise control blocks to fit plant-specific nuances in operation and control using the built-in Model Editor. Benefit from built-in templates as well as inline syntax check and error detection, code snippets and code verification.

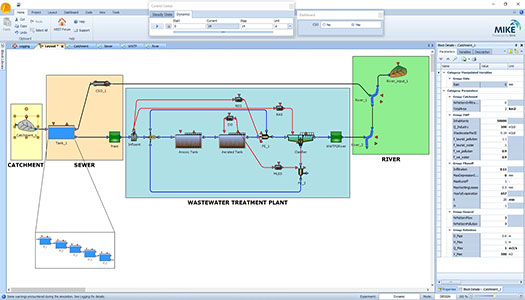

To run complex, integrated models on one software platform

Accurately calculate the carbon footprint of your WWTP and identify the most important sources to GHG emissions

To calculate the carbon footprint of your WWTP and achieve more sustainable operations

Integrated Urban Water Systems (IUWS) library extensions

WEST users now have access to three new models to help deliver more accurate predictions of inflows and solids loading to WWTPs during both dry and wet weather conditions.

- Rely on the new rainfall-derived infiltration and inflow model to conduct integrated assessments of sewer systems, WWTPs and recipients

- Evaluate the impact of CSOs on recipient quality with a simplified catchment model for influent generation

- The new Particle Size Velocity Distribution (PSVD) model is ideal for influent forecasting in digital twin applications

More accurately predict inflows and solids loading to WWTPs during both dry and wet weather conditions with three new WEST Integrated Urban Water Systems (IUWS) models

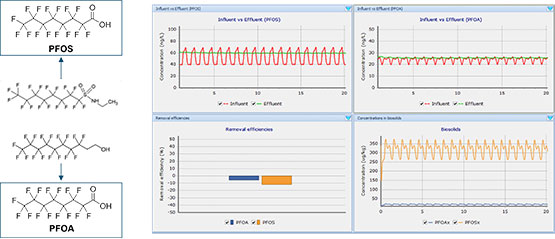

Model the discharge, fate and removal of PFAS contaminants

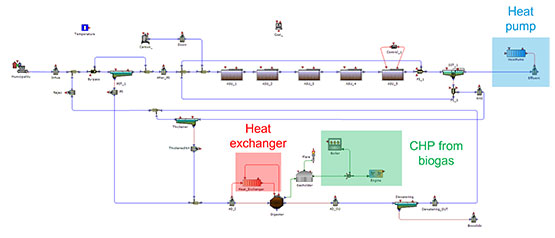

Model heat recovery from effluents using heat pumps

LinkedIn feeds

Make WEST your modelling platform of choice

Plant Operators

Wastewater Engineers & Consultants

Researchers

No in-house modellers?

Be inspired by how these WWTPs were improved through the application of WEST modelling and simulation

"We chose WEST for its great capabilities in describing biological processes in wastewater treatment systems and its high potential for customisation through the creation of new process models and process units that are not present in the standard library. Furthermore, the intuitive graphical user interface and the ease of importing our own data allowed us to rapidly build complex plant layouts, such as the one of Ravenna WWTP (240,000 PE)."

- Ida Basta, Process Engineer, HERA S.p.A.

Featured software subscription package

Wastewater Treatment

Develop digital twins, implement new control strategies and optimise plant operations using the open and flexible software platform, WEST+, for advanced process modelling and statistical analyses.

Additional capabilities & unique features

WEST now enables users to effortlessly take one or multiple tanks out of operation for maintenance or dynamic conditions, ensuring uninterrupted plant functionality and efficient maintenance scheduling. Gain precision by sequentially emptying and filling tanks in series, optimising workflow and enhancing simulation accuracy. Unlike regular fixed-volume tanks, our solution ensures numerical stability, providing dependable and accurate results. Explore these capabilities confidently with the included demo project, allowing you to master activated sludge management for more efficient wastewater treatment. Watch the video

Unlock access to an advanced evaporation model within IUWS (1, 2, and 3) instances, grounded in the esteemed Penman-Monteith equation. This model, endorsed by UN FAO for potential evapotranspiration (ETo), guarantees heightened accuracy in your simulations. Recognised as the foremost method for determining reference evapotranspiration, it ensures dependable and authoritative results. Dive into mastery of this potent evaporation modelling tool confidently, aided by our included demo project. Watch the video

WEST users now have the option to choose folder destinations when saving or loading snapshots to neatly categorise multiple runs and make tracking and retrieval a breeze. Bid farewell to compatibility issues as you receive instant notifications regarding data compatibility when browsing specific folders. Unlike previous versions, now you can save multiple sets of results per project, freeing you from the constraints of a single set and enabling exploration and comparison of various simulation outcomes. Unleash the full potential of your simulation snapshots confidently with the aid of our included demo project. Watch the video

Experience a revolution in micropollutant management with our integrated library. This feature empowers you to simulate micropollutant occurrence and destiny from source to treatment plant, model discharges from households and industries, predict removal in treatment processes, and identify key removal mechanisms. Plus, explore its capabilities with a demo project. Watch the video

It’s now possible to dynamically calculate a commonly used set of key performance indicators (KPI’s) in WEST for energy use and recovery, resource use, and CO2 footprint. Rely on this information for energy audits, when ranking operational strategies or to compare energy, resource and cost efficiency in relation to other WWTPs.

With WEST’s new granular partial nitritation/anammox treatment process unit model, you can evaluate sidestream nitrogen removal through accurate description of transport and conversion processes in bulk and in granules. Diffusive transport inside the granules, as well as concentration profiles of solubles and particulates, are described based a variable number of discretization layers.

WEST’s recently updated catchment, sewer and river model library offers an improved description of in-sewer processes, enabling users to better predict hydrogen sulfide emissions. Check out the dedicated integrated urban water system demo model – now available as a sample project with the WEST installer. Learn more

A Thermal Hydrolysis (THP) unit process model has now been made available for all instances, not just PWM_SA.

For greater insight into energy recovery and utilisation from biogas, be sure to check out WEST’s latest demonstration project, an extension of Benchmark Simulation Model no.2 (BSM2) with a unique energy/biogas layer – now available as a sample project with the WEST installer. Watch the video

Are you interested in using WEST but have little experience in process modelling? You can start by using WEST Basic, our new entry-level product to construct and simulate simple plant layouts.

WEST now includes a comprehensive model for Carbon, Nitrogen, Phosphorus, Sulfur and Inorganic Solids. With this information, you can evaluate strategies to reduce carbon footprint by minimizing GHG emissions, identify potential threats associated with gaseous emissions (H2S), assess the implementation and operation of novel treatment technologies (Anammox), and quantify the impact of inorganic solids on sludge production and disposal costs – all with one modelling platform.

Perform a comprehensive evaluation of energy and resource recovery potential using a new suite of unit models. You can also identify the most suitable strategies for on-site heat and energy reuse towards energy neutral and resource efficient operation.

When studying novel treatment approaches, software tools are to be both sufficiently flexible to capture newly acquired knowledge, such as models and data, and fast enough to evaluate a large number of alternatives within a reasonable timeframe. WEST excels in both areas, as demonstrated by its Block Editor and Model Editor applications (for developing custom model libraries) and the availability of the WEST engine on a number of high performance computing (HPC) infrastructures and supercomputers.

Modelling of WWTP process dynamics (in view of optimal control design) requires high-frequency input time series, which may not always be available from on-site measurements. With WEST, you can define the time series for influent quantity and quality based on essential information in the served catchment and several pre-defined discharge patterns.

Determine energy balances and costs to identify pitfalls and inefficiencies in WWTP operations and assess optimisation potential. Support decision-making to increase efficiency and reduce energy footprint in specific process units and at plant-wide level using detailed energy and cost calculations in WEST.

Create a digital twin of your WWTP to predict the dynamic response to variations such as the influent water quantity and quality. Identify sensor drift and equipment anomalies using DHI’s online data validation tools along with WEST models to identify and track long-term shifts in plant loadings and microbial populations. Use calibrated WEST models to train operators and test alternative operational scenarios in an offline simulation environment. Understand the integrated nature of WWTP processes using custom dashboards, graphical outputs, defined control handles and the Advanced Experiments (such as Scenario Analysis) tools.

Access detailed models for centrifugal and positive displacement pumps and blowers along with control models for different configurations of multiple pumps and blowers in parallel.

Novel biological processes are being developed to enhance carbon capture, rather than mineralization, by microorganisms in order to increase energy recovery in downstream processes. With WEST, you can describe these processes that can be seamlessly interfaced with other process models.

The excess sludge of a wastewater treatment plant contains valuable resources (material and energy) that can be harvested, thereby reducing the overall cost of operating a facility. Use the anaerobic digestion, stripping, precipitation / crystallization and scrubbing unit process models to simulate a nutrient and energy recovery sludge treatment train.

Inorganics can represent a considerable fraction of suspended solids entering a WWTP and have a significant impact on the operation of mechanical equipment and sludge production. A novel process model is now present in WEST to provide a detailed description of the fate of ISS throughout the different units of a WWTP, eventually allowing for a more precise quantification of sludge handling and disposal costs.

A number of tertiary treatment units, such as sand filtration, chlorination and UV disinfection, are now available in the WEST block library.

Simulate water quality in sewers, a WWTP and water recipients (such as rivers) using the integrated urban water systems (IUWS) model library. Identify synergies, determine and minimise impacts on downstream environments and globally optimise wastewater system performance.

Take advantage of the dedicated add-on with models of OSMART® control logic. OSMART® is an algorithm developed by E.T.C Sustainable Solutions (Trento, Italy) to control intermittent aeration in activated sludge processes. It features several economical and environmental benefits in the operation of a wastewater treatment plant. Read more

Model calibration is an essential part of the model development process. With WEST, you can identify operational parameters that influence plant performance using the Local and Global Sensitivity Analysis. In addition, WEST allows you to efficiently calibrate your model using the dedicated Parameter Estimation tool. Evaluate WWTP response under uncertain and variable boundary conditions and biokinetics using the Uncertainty Analysis and Scenario Analysis tools.

WEST makes it easy to access your project information in one place. Relevant information present in a WEST project (plant layout, user’s notes, graphical output) can be gathered in a single document through the rich text notes and automated report generation feature.

The latest release of WEST is shipped with two model libraries: the traditional MSL library and a brand new Modelica library. Modelica is a modeling language with better features and much more widely used than MSL. The Modelica library will gradually replace the MSL library, which will not be further developed.

A variety of APIs are available on top of the WEST back-end (Tornado), the most comprehensive being the .Net API. Other APIs include, C++, JAVA/JNI, OpenMI, MATLAB/MEX, etc.

Let's get started

Complete this form and we will be in touch soon.